59 11 window Splitty Custom Resto

Moderators: warb, Rawdyn, Leroy, byronbus, Tonz Magonz, dmb

-

zeuspig

- DSKer

- Posts: 1218

- Joined: Tue Apr 03, 2007 5:00 pm

- Location: Sunshine Coast

- Tonz Magonz

- Mod

- Posts: 4085

- Joined: Tue May 17, 2005 9:13 pm

- Location: Melbourne mostly

-

Hoves

- DSKer

- Posts: 1085

- Joined: Mon Oct 30, 2006 4:46 pm

- Location: Queensland

- shark

- DSKer

- Posts: 967

- Joined: Mon Aug 25, 2008 3:14 pm

- Location: Northern Beaches, Sydney

- tombi (aka type2tommy)

- DSKer

- Posts: 872

- Joined: Tue Mar 14, 2006 10:44 am

- Location: In da hood

-

67seeker

- DSKer

- Posts: 27

- Joined: Sun Feb 05, 2006 9:30 am

There's no doubt Al and the boys fall into the Artisan category. We know that heavily customised is not for everyone so the positive comments and interest are appreciated. Those that know me would confirm my lack of technical ability so I defer to Al regularly

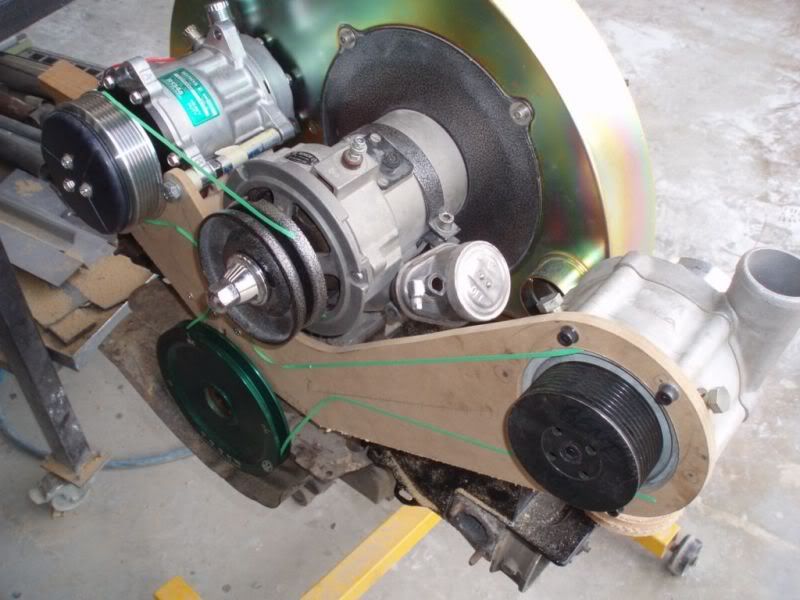

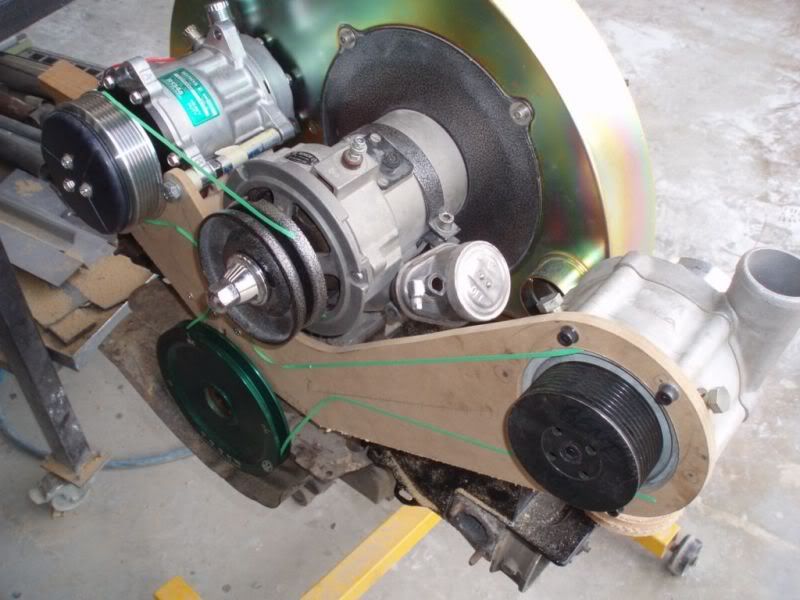

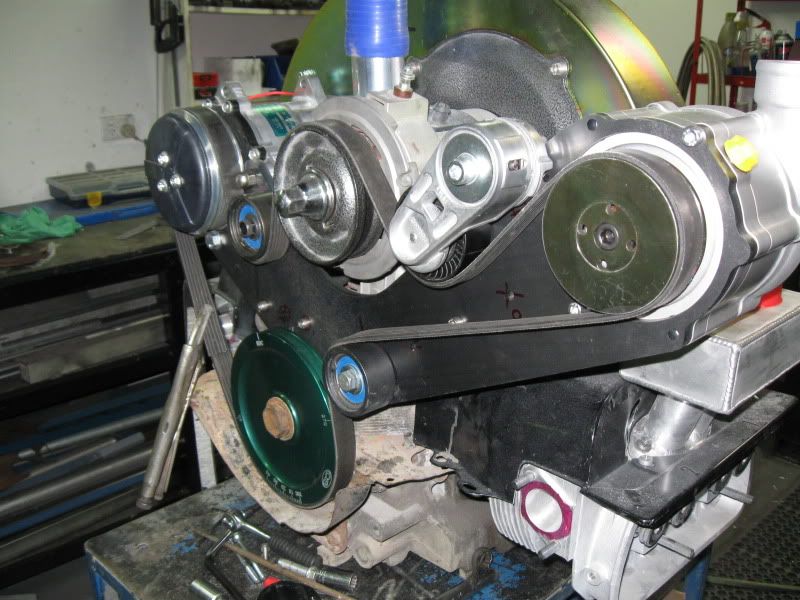

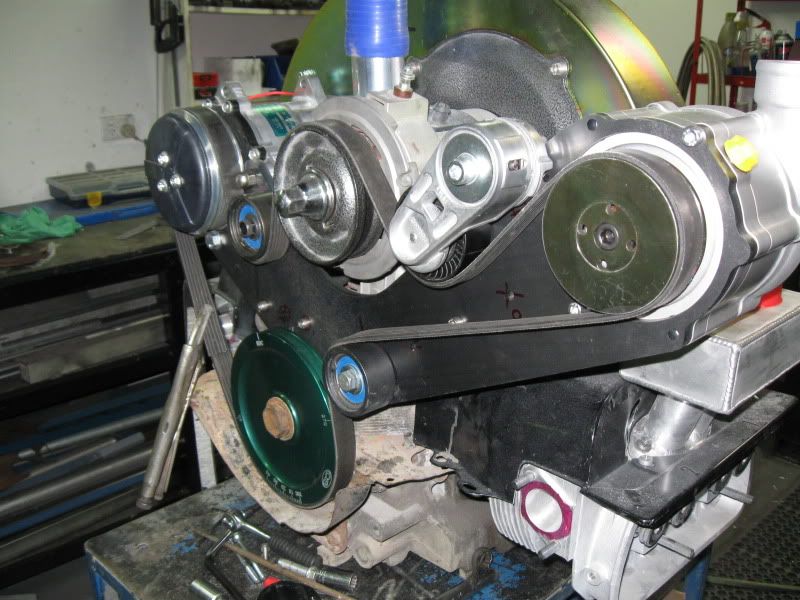

To be a little different we decided to step outside the box and incorporate a Rotrex supercharger onto the engine. As mentioned before this will enable us to have loads of torque on tap (especially with the custom Plazmaman water to air intercooler and single throttle body fuel injection)....whilst keeping the 2275cc motor fairly sedate (mild camshaft grind, mild heads etc). This was an early mockup of the AC compressor and supercharger faceplate/bracket.

Al tells me the inlet manifold plenums had to be rectangular to allow for adequate inlet runner length (which are bell mouthed inside the plenums), but also to be low enough to clear the supercharger

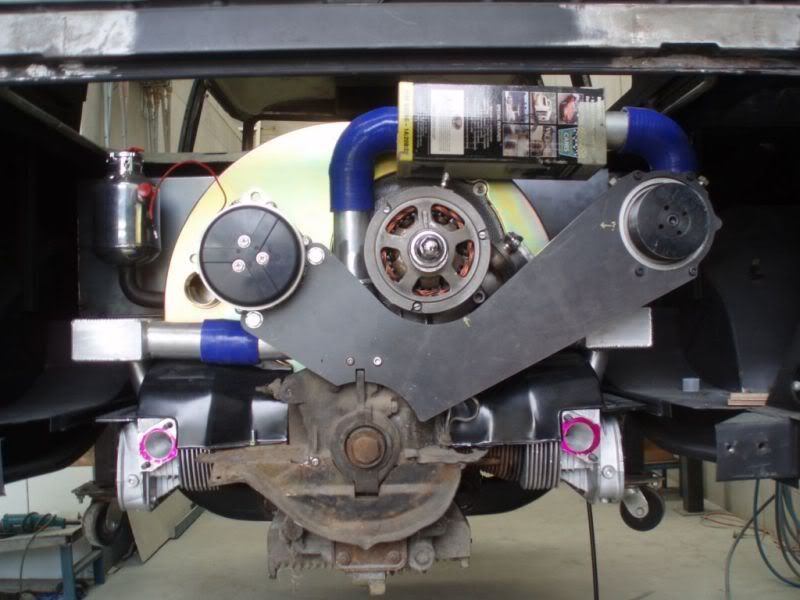

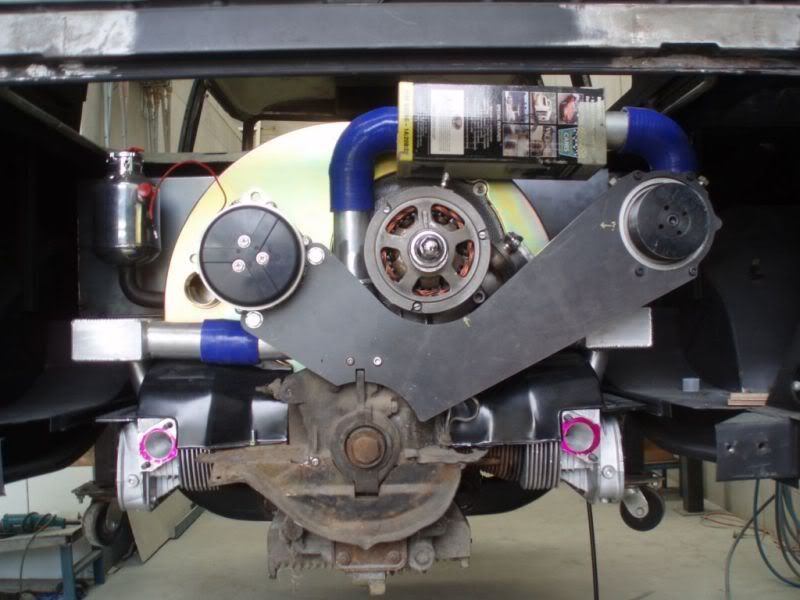

Another mockup of the engine in the bus with a makeshift intercooler to get the position and size right before ordering

A custom mounting ring had to be machined to adapt the holden throttle body to the Rotrex supercharger – this is double o-ringed inside to seal

With the vast number of ancillaries in the engine bay, access was very important so a T3 hatch was grafted in but was narrowed to match the width of the rear hatch

Water pump for intercooler was tucked in beside the custom fuel tank

Reservoir for intercooler system was made by PWR and mounted on the tank face

A look to the current day shows how far the paint detailing and careful planning of plumbing has come...

There are a lot of subtle details that won’t be picked up by most but take a lot of time to perform including the removal of the original rear hatch stay/prop slot to facilitate the gas struts

A big package arrived from the UK a while back which was exciting being the first one in Oz

A lot of time has gone into the design of the Red9 Design front end which eliminates the original torsion beam front end and incorporates coil overs and double wishbones

Two pack paint detailing on pretty much everything that is bolted onto the bus!

Porsche front hubs were modified to fit on the bay window (modified by Red9) spindles allowing the bearings and calliper spacings to work without any calliper brackets/adaptors

Of course extensive consultation occurred with engineer who is overseeing all the mods before ordering the front end – apart from a couple minor changes he is thus far happy with what he sees.

To be a little different we decided to step outside the box and incorporate a Rotrex supercharger onto the engine. As mentioned before this will enable us to have loads of torque on tap (especially with the custom Plazmaman water to air intercooler and single throttle body fuel injection)....whilst keeping the 2275cc motor fairly sedate (mild camshaft grind, mild heads etc). This was an early mockup of the AC compressor and supercharger faceplate/bracket.

Al tells me the inlet manifold plenums had to be rectangular to allow for adequate inlet runner length (which are bell mouthed inside the plenums), but also to be low enough to clear the supercharger

Another mockup of the engine in the bus with a makeshift intercooler to get the position and size right before ordering

A custom mounting ring had to be machined to adapt the holden throttle body to the Rotrex supercharger – this is double o-ringed inside to seal

With the vast number of ancillaries in the engine bay, access was very important so a T3 hatch was grafted in but was narrowed to match the width of the rear hatch

Water pump for intercooler was tucked in beside the custom fuel tank

Reservoir for intercooler system was made by PWR and mounted on the tank face

A look to the current day shows how far the paint detailing and careful planning of plumbing has come...

There are a lot of subtle details that won’t be picked up by most but take a lot of time to perform including the removal of the original rear hatch stay/prop slot to facilitate the gas struts

A big package arrived from the UK a while back which was exciting being the first one in Oz

A lot of time has gone into the design of the Red9 Design front end which eliminates the original torsion beam front end and incorporates coil overs and double wishbones

Two pack paint detailing on pretty much everything that is bolted onto the bus!

Porsche front hubs were modified to fit on the bay window (modified by Red9) spindles allowing the bearings and calliper spacings to work without any calliper brackets/adaptors

Of course extensive consultation occurred with engineer who is overseeing all the mods before ordering the front end – apart from a couple minor changes he is thus far happy with what he sees.

-

Hoves

- DSKer

- Posts: 1085

- Joined: Mon Oct 30, 2006 4:46 pm

- Location: Queensland

- Dasdubber

- DSKer

- Posts: 1847

- Joined: Thu Dec 01, 2005 10:18 pm

- Location: Gold Coast

G'day Tony, the one limitation of the front end is that is a fixed width so rim choice and offset is important. The 17 x 7 rims we had made by Iozzio in the US did clear the wishbone and doglegs (140mm backspacing) at a moderately lowered height, however when going low there were interference issues with the dogleg lips on full lock (early big lip doglegs).Tonz Magonz wrote:Awesome ideas and skills.....

Are there any clearance issues with the chosen rim size (17"x7"?) and the Red9 front end regarding limitations to ride height..?

Cheers Tony

Since we wanted the bus fairly low, we ended up selling the 17 x 7 rims and had another pair made that are 17 x 6 but with the same offset - only just got these so will refit shortly.

You could go quite low with 15in rims however 17s do create some challenges at times - worth the effort though as they will look great on the bus.

Cheers

Al

PS Mick - definitely welcome for a visit any time to come and check out Armando's bus

-

67seeker

- DSKer

- Posts: 27

- Joined: Sun Feb 05, 2006 9:30 am

-

headstone

- DSKer

- Posts: 245

- Joined: Mon Oct 26, 2009 10:05 pm

- Location: geelong

-

67seeker

- DSKer

- Posts: 27

- Joined: Sun Feb 05, 2006 9:30 am

For me the enjoyment has been/ continues to be the journey - the guys brainstorm a lot and each time I visit I'm reminded of their skills....

This was the last engine mockup prior to having the final version of the face plate laser cut – custom crank and alternator pulleys have since been machined to work with the 6PV (rib) serpentine style belt.

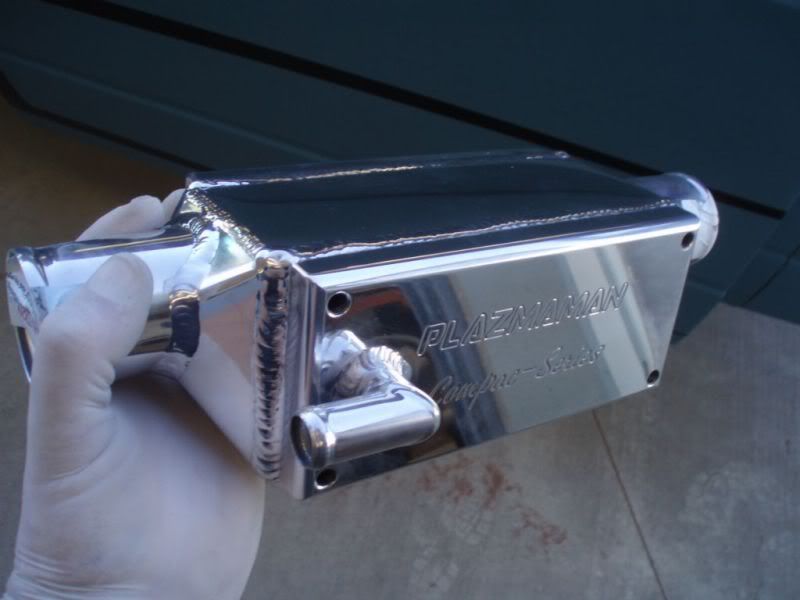

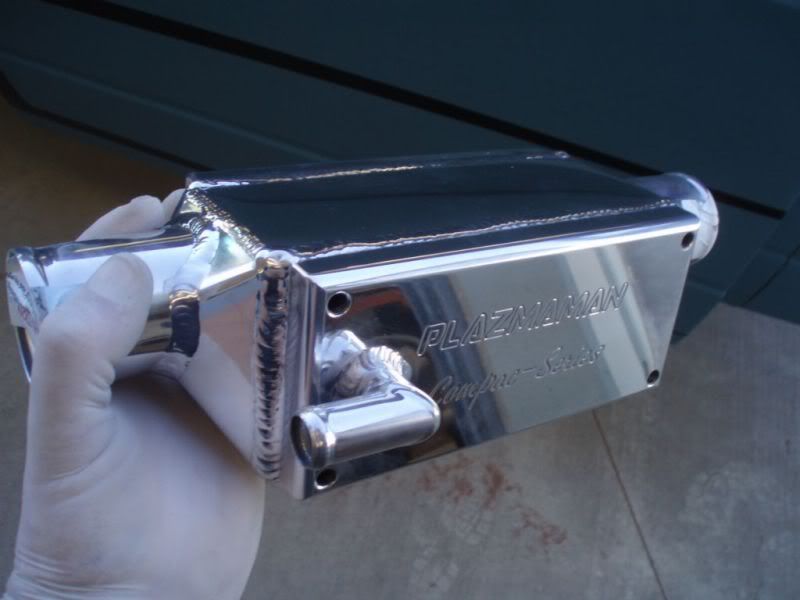

The polished Plazmaman water to air intercooler – due to design of the core water inlet/outlets couldn’t both be placed on the back side

Although the original 17in Iozzio Fuchs fitted well, I decided to get a little more ‘deeper dish’ look on the rears so these wheels were on sold and a new set were made (pics to come soon as they just arrived in the country).

To get the deeper/wider rims to fit on the rear, Al, Rob and Steve had to narrow the rear torsion housing

Fortunately Rob (at DAS Resto Haus) has been employed by a number of race car engineering firms in previous roles (also has done several stints driving in the US and UK) so he made a comprehensive set of measurements and datum lines to ensure suspension geometry was exactly where he wanted it.

Custom bump stops were fabricated for the rear

Compression measurements of the bump stops were taken to get the positioning perfect to ensure no tyre interference problems occurred down the track

A set of 16in Fuchs were bolted on post-narrowing process to check clearance whilst waiting for the new 8in 17in Fuchs

This was the last engine mockup prior to having the final version of the face plate laser cut – custom crank and alternator pulleys have since been machined to work with the 6PV (rib) serpentine style belt.

The polished Plazmaman water to air intercooler – due to design of the core water inlet/outlets couldn’t both be placed on the back side

Although the original 17in Iozzio Fuchs fitted well, I decided to get a little more ‘deeper dish’ look on the rears so these wheels were on sold and a new set were made (pics to come soon as they just arrived in the country).

To get the deeper/wider rims to fit on the rear, Al, Rob and Steve had to narrow the rear torsion housing

Fortunately Rob (at DAS Resto Haus) has been employed by a number of race car engineering firms in previous roles (also has done several stints driving in the US and UK) so he made a comprehensive set of measurements and datum lines to ensure suspension geometry was exactly where he wanted it.

Custom bump stops were fabricated for the rear

Compression measurements of the bump stops were taken to get the positioning perfect to ensure no tyre interference problems occurred down the track

A set of 16in Fuchs were bolted on post-narrowing process to check clearance whilst waiting for the new 8in 17in Fuchs

- shark

- DSKer

- Posts: 967

- Joined: Mon Aug 25, 2008 3:14 pm

- Location: Northern Beaches, Sydney

As I earlier said Amando it is a credit to you all am loving following the design process. I love design and I have had more fun than I could remember working through ideas with Al and the boys. I am again in that stage with Isurus my SC and it is great to push the envolope

Customs are not for everyone but for me it is like keeping the best of the past and updating it to today

Customs are not for everyone but for me it is like keeping the best of the past and updating it to today

I know what I am doing - I Think ?

-

travellinbob

- DSKer

- Posts: 220

- Joined: Mon Apr 23, 2007 4:43 am

- Tonz Magonz

- Mod

- Posts: 4085

- Joined: Tue May 17, 2005 9:13 pm

- Location: Melbourne mostly

Thanks Al...Dasdubber wrote:G'day Tony, the one limitation of the front end is that is a fixed width so rim choice and offset is important. The 17 x 7 rims we had made by Iozzio in the US did clear the wishbone and doglegs (140mm backspacing) at a moderately lowered height, however when going low there were interference issues with the dogleg lips on full lock (early big lip doglegs).Tonz Magonz wrote:Awesome ideas and skills.....

Are there any clearance issues with the chosen rim size (17"x7"?) and the Red9 front end regarding limitations to ride height..?

Cheers Tony

Since we wanted the bus fairly low, we ended up selling the 17 x 7 rims and had another pair made that are 17 x 6 but with the same offset - only just got these so will refit shortly.

You could go quite low with 15in rims however 17s do create some challenges at times - worth the effort though as they will look great on the bus.

Cheers

Al

PS Mick - definitely welcome for a visit any time to come and check out Armando's bus

Will be going for 15" on the next incarnation,so the red 9 should be fine..

Great work by you and Rob..

Wanted..Barny bits or 60's Supercharger other than Judson