Spent a little bit of time messing around with the tail lights for the bus today.

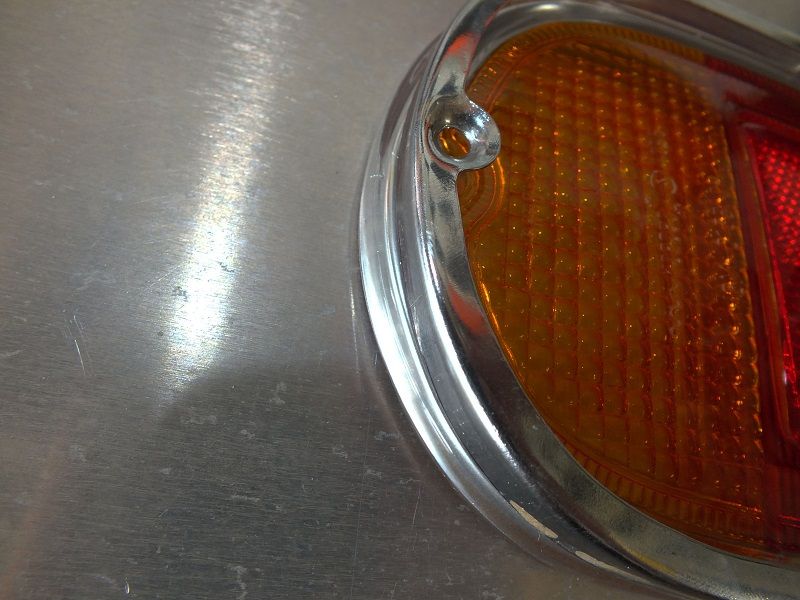

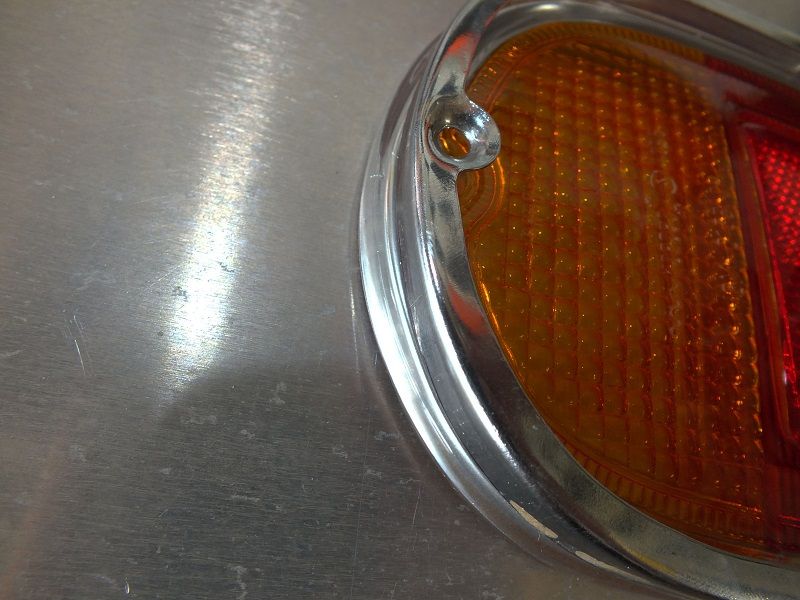

I've always been a fan of tail lights with a chrome bezel but I couldn't seem to find any apart from the all red US spec ones. I wasn't really all that keen on running the stock Red and Amber lenses with the painted silver style bezel built into the plastic.

So, I decided I would just fit the chrome bezel over the lenses.... But when I had all of the parts, I realised it wasn't going to be that simple.

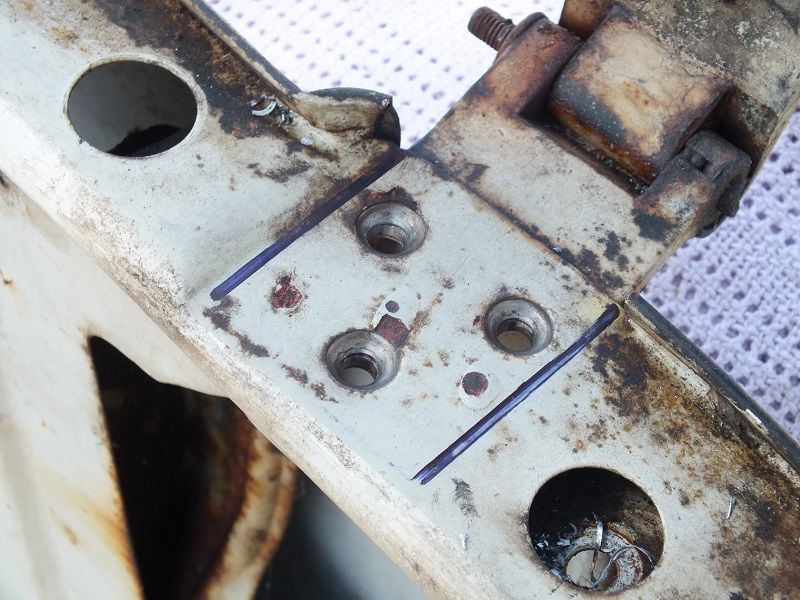

As you can see from this pic, the Hella lense is too large for the chrome bezel...

and the screw hole sticks out the back of the lense too far, not allowing it to sit flush...

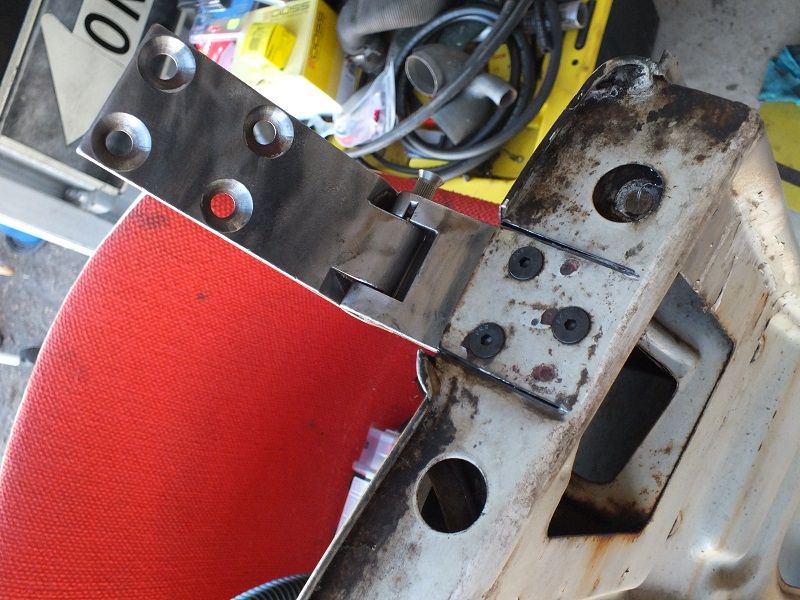

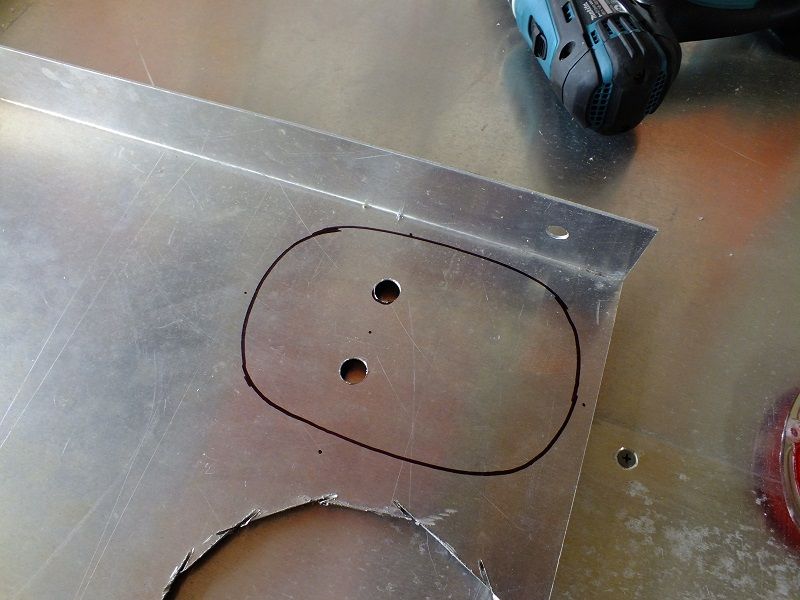

I started by using the bezel as a guide and marking out how much plastic I needed to remove from the outside edge to ensure the bezel will fit over...

Having ground off the excess from the edges it was now time to remove the bulk of the screw hole so the lense would sit flush at the base...

The bezel now fits around the outside...